High FFA Pretreatment

High FFA Pretreatment

Pretreatment is absolutely necessary for anyBiodiesel Plant wishing to incorporate crude degummed oils, waste vegetable oil (WVO), jatropha, palm, beef tallow, choice white grease, poultry fat, and various other inferior oils other than RBD . All of these oils come with 2%-15% FFA and will consume large amounts of methylate and methanol which produce water and soaps that contaminate, centrifuges, piping, pumps, and vessels on any future batches.

What is “Pretreatment” and why is it needed?

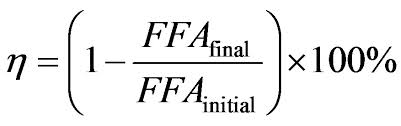

- Pretreatment describes any and all steps required to prepare feedstock for transesterification. This most commonly involves water removal and converting FFA into useable oil.

- Any water left in oil causes soap production during transesterification

- Soaps can clog lines, impede optimal reactions, and result in equipment downtime

- FFA (Free Fatty Acids) are fats that exist in a variety of new and used oil sources:

- Waste Vegetable Oil (WVO) FFA are created when fatty foods are fried

- New Oils: Corn Oil, Rapeseed, Jatropha and many other agricultural feedstocks make excellent oils for biodiesel, but all have FFA levels too high for transesterification. They must be pretreated first.

Some Examples of High FFA Oils

Algae |

Jatropha |

Palm Oil |

What are the options for Pretreatment?

Two methods exist for removing FFA from feedstock:

- Caustic Stripping. Caustic is used to “strip” FFA from oils. Caustic reacts with FFA to create soaps, which result in significant yield loss and creates a disposal issues with soaps that are produced

- Acid Esterification. Methanol and sulfuric acid are mixed with oils, and FFA is converted into methyl esters. This process results in no yield loss and no soap production.

The FSP-Series System:

If feedstock contains FFA (Free-Fatty Acids) in excess of 1%, it is recommended that it be pretreated. Pretreatment options include (Acid Esterification or Caustic Stripping). SRS has designed an exclusive system (FSP-Series/Continuous Flow Acid Esterification System) which utilizes the proven method of using Methanol and Acid to convert FFA into usable oils as opposed to simply caustic washing them out leaving a considerable yield loss. SRS further adds to this process a proprietary process of utilizing a modified waste additive to remove excess water from the oil prior to a transesterifcation process to further prevent the development of soap production. Through the use of proprietary technology, (The SRS FSP-Series Unit) it is now possible to convert feedstocks containing up to 15% FFA into usable fuel, eliminating soap production, and provide a 100% yield even with the most inferior oils.

Advantages of a Pretreatment System (FSP-Series System):

- Removes water content

- 100% FFA conversion

- Prevents soap creation

- Up to 15% FFA Feedstocks

- Energy Efficient

- Fast return on investment

- Cost savings

- Post treatment

- Dry wash

- Ion-exchange treatment

- Methanol Recovery/Purification

How does the FSP system implement work?

- The SRS FSP system is a continuous flow acid esterification system.

- The FSP system precisely meters methanol and sulfuric acid into feedstock, converting FFA into saleable oil prior to transesterification.

What technologies does SRS employ to be able to guarantee the performance of the FSP?

While the specifics are proprietary, SRS has engineered the FSP to use heat, pressure, static mixing, and special dosing methodologies to obtain optimal conversion rates at flow rates from 500K-150 million gallons per year.

SRS’ proprietary pretreatment unit is less expensive than other units that are designed to remove the FFA saving you lost volume and money and allowing you to render the FFA to salable oils. This increases product yield and bottom line profit. Without the pre-treatment/esterification process, a BioDiesel plant will operate with little to no profit margin.

The FSP-Series unit represents a complete package capable of handling all of your Biodiesel Engineering needs at a competitive price. The FSP is currently being integrated into numerous existing operational and unoperational Biodiesel plants throughout North America and are an essential component of an SRS BioDiesel “Turn Key” Plant.

Why Choose SRS’ FSP Series?

Scalable – from 500k to 150MMGY per year

Capable – only product line offering ability to handle up to 15% or higher FFA

Agile – enables biodiesel plant operators to be multi-feedstock capable

Reliable – continuous flow, automated, with remote monitoring capability

Safe – Intrinsically safe wiring, nitrogen purged panels, integrated safety features

Proven – Over 25 years of process technology experience built into every system